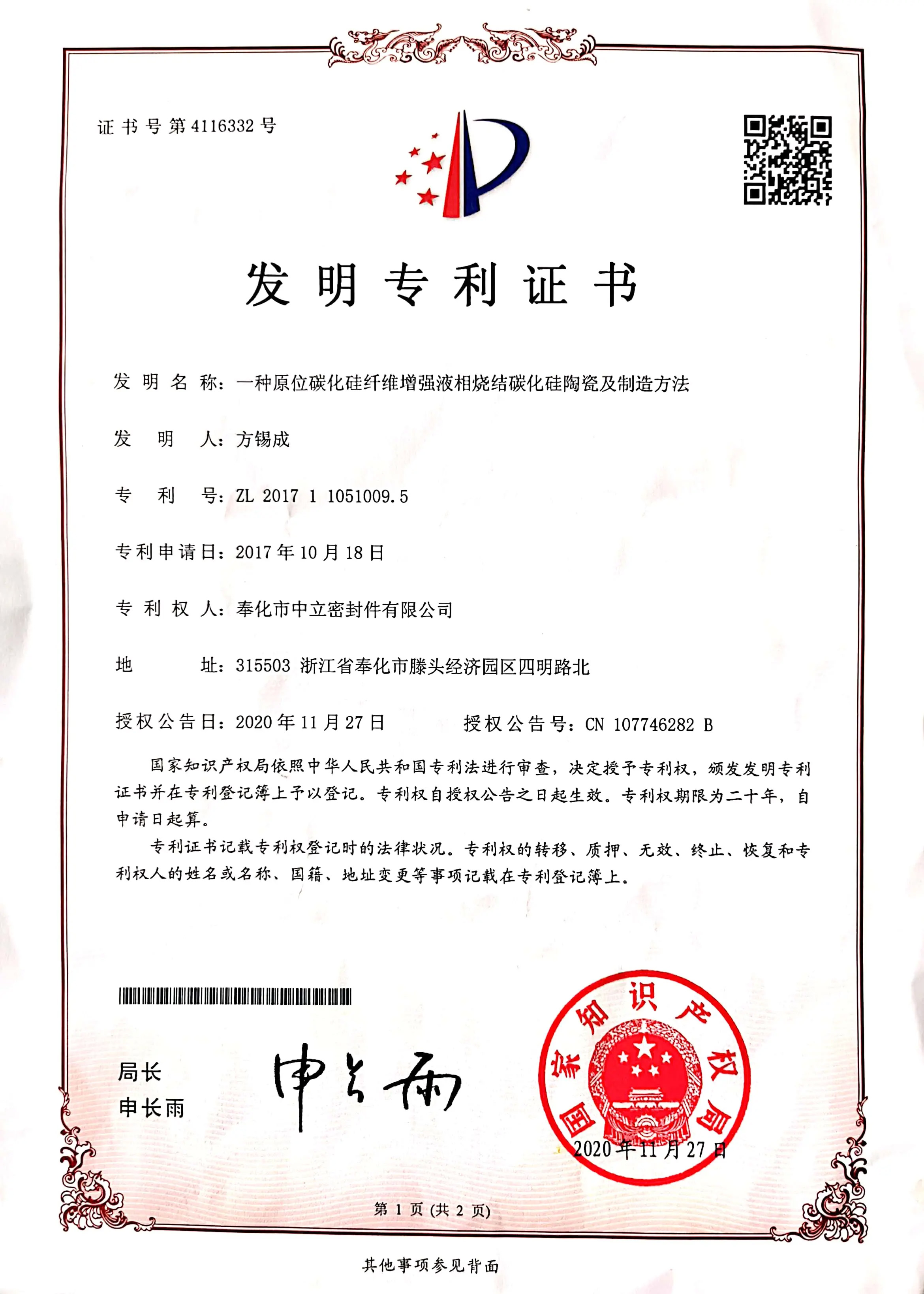

In December 2020, the new silicon carbide material for mechanical seals newly developed by our company (an in-situ silicon carbide fiber reinforced liquid phase sintered silicon carbide ceramic and its manufacturing method) was an invention issued by the State Intellectual Property Office patent certificate.

Since the 1980s, silicon carbide materials have been widely used in the field of mechanical seals. With the advancement of technology and the higher and higher requirements of the working conditions of mechanical seals, the use of pressureless sintered silicon carbide materials has become more and more widely used. However, due to the complex production process of traditional pressureless sintered silicon carbide sealing materials, the sintering temperature is high. The output is low, resulting in expensive SSIC and a long production cycle.

In order to solve the problems of high production cost and long production cycle of SSIC products, the company invested nearly 1 million U.S. dollars in the past three years to conduct rigorous and effective scientific research on this problem. With the careful guidance of a doctoral professor at Ningbo University, we finally achieved success.

This new SSIC material cuts the production time by half and reduces the production cost by about 30%. It can use special production technology to produce a complex structure of SSIC sealing ring, and the firing shrinkage rate of this SSIC is stable, and the size is available, and more importantly, the performance indicators of this SSIC fully meet the current SSIC technical standards.

Because it has the characteristics of low cost and short production cycle, it is expected to obtain huge market benefits and will be welcomed by the mechanical seal industry.

Our company warmly welcomes the world’s major mechanical seal manufacturers to order and try this new low-price SSIC sealing material, and we will supply it to you at a price 30% lower than the ordinary SSIC.